Fanfold labels vs. roll labels determining which is best for your product packaging

Overview of Roll and Fanfold Labels

Labels help identify products, shipments, inventory, hazardous materials, and much more. Two of the most common types are fanfold labels and roll labels.

Fanfold Labels

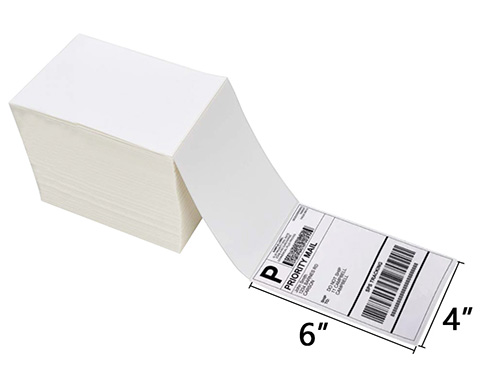

Fanfold labels, sometimes called pinfeed labels, are continuous sheets of labels that are folded in a fanfold or accordion style. The labels are connected together with perforations and holes/notches along the edges for pinfeed printers.

Fanfold labels are available in a range of standard sizes like 4 x 6, 4 x 2, and 2 x 4 inches. You can also find options for larger shelf or warehouse labels. They usually come packed in boxes containing multiple fanfolded stacks.

Roll Labels

Roll labels come wrapped around a central core, similar to a roll of tape. The backside of the labels has a strong adhesive, so they can be easily peeled off the liner and applied. Rolls come in varied lengths and widths.

Some common roll label sizes are a 2-inch core with rolls from 250 to 1,000 labels. Rolls can also have a 3-inch core and range from 2,000 to over 15,000 labels. The exact length depends on the label size and layout.

Key Differences Between Fanfold and Roll Labels

While both fanfold and roll labels serve the same general purpose, there are some notable differences between the two formats:

- Fanfold labels have perforations and pinfeed holes for continuous printing. Roll labels are wound around a core.

- Fanfold labels allow printing of one or multiple labels in batches. Roll labels are often pre-printed.

- Fanfold labels work with pinfeed printers. Roll labels work with thermal transfer printers.

- Fanfold labels are better for variable data printing. Roll labels are ideal for large pre-printed jobs.

- Fanfold labels take up more storage space. Roll labels have a smaller footprint.

Features of Fanfold Labels

Fanfolds provide a variety of benefits in performance and customization. Let’s examine some of the key features of fanfold labels:

Size and Shape Variety in Fanfold Labels

One of the benefits of fanfold labels is the wide selection of sizes and shapes available. Here are some of the common options:

- Standard rectangles and squares ranging from 1 x 1 inches to 4 x 6 inches

- Ovals, circles, diamonds, and triangles

- Binder spine labels in longer strips

- Shipping and warehouse labels in larger formats

- CD/DVD labels in a fanfold sheet

This extensive variety makes it easy to find the perfect label for any application. Fanfold layouts allow custom labels on demand.

Advantages of Fanfold Labels

There are several notable advantages of using fanfold labels, including:

- Efficient variable data printing: Fanfold labels feed continuously through pinfeed printers, allowing easy batch printing of variable information on each label.

- Less waste: You can print the required number of labels instead of using full rolls.

- Cost effective: Fanfold labels provide economical small-quantity label runs.

- Specialty label materials: Fanfold labels are available in weatherproof, freezer, and security label stocks.

Easy organization: The boxed fanfold stacks keep unused labels neat and protected.

Fanfold labels are a versatile option suitable for many labeling applications and printer setups.

Attributes of Roll Labels

Roll labels offer many advantages that make them a versatile and popular label format. Some key attributes of roll labels include:

Greater Versatility

Roll labels come in a continuous format on a roll, which allows them to work with high-speed auto-applicators and printers. This makes them highly versatile for large-volume labeling projects across many industries. Roll labels can be cut to any length and printed with variable information like barcodes, ingredient lists, and more.

Roll label materials range from paper to flexible films like BOPP, vinyl, and polyester. With options like direct thermal, thermal transfer, laser, inkjet, and flexographic printing, roll labels support virtually any need.

Advantages of Roll Labels

Compared to other label formats like sheets or fanfolds, roll labels offer advantages like:

- High-speed printing and application

- Very high label counts per roll for large-volume runs

- Flexible films offer durability for tough environments

- Range of adhesives available for different surfaces

- Variety of materials and print methods for any labeling need

- Efficient storage saves space

- Lower material waste compared to sheets

- Cost-effective choice for high-volume labeling

With this combination of efficiency, versatility, and convenience, it’s easy to see why roll labels are a top choice for many industries and applications.

Making the Decision: Roll or Fanfold Labels?

When considering a label printing project, one key decision is whether to choose roll or fanfold labels. While both offer advantages, some key factors can help determine which is the better fit.

Key Factors to Consider: Volume, Production Speed, and Storage Space

Roll labels are ideal for high-volume label runs, as they offer more labels per roll and faster printing/application speeds. However, fanfolds take up less storage space for lower volume jobs. The optimal choice depends on your typical order volumes and production environment. For example, a contract packager producing 50,000+ labels per order for various food companies would benefit most from roll labels. But a small brewery printing 500–1,000 labels at a time may find fanfolds more practical.

Evaluating Your Industry-Specific Packaging Needs

When it comes to packaging, one size does not fit all. Your industry has its own rhythm and demands, and that’s where the choice between roll and fanfold labels comes into play. With nearly four decades of helping customers make the right decision for their brand, Accu-Label can offer invaluable insights into which label format is best for you.

Let’s delve into the specifics and discover which format is your industry’s ultimate choice.

Food and Beverage

Imagine your delectable creations flawlessly packaged and labeled. Roll labels are the unsung heroes of the food and beverage industry, seamlessly handling the rapid pace of bottling and packaging lines. Plus, they’re resistant to humidity and meet the challenges of refrigerated and frozen storage.

Beer, Wine, and Spirits

Crafting liquid poetry? For boutique wineries and artisanal brewers, fanfold labels offer the ultimate flexibility. But if you’re a titan in the world of beer, wine, and spirits, roll labels streamline your production line for optimum efficiency. Cheers to finding the label that matches your spirits, no matter the size of your batch.

Chemical

Chemicals demand precision and durability in every aspect. Roll labels have the specialized materials to meet GHS regulations, ensuring compliance while avoiding the notorious gaps that fanfold labels can sometimes bring. When safety and compliance are paramount, roll labels are the way to go.

Automotive

From inventory management to tiny yet crucial warning labels, the automotive industry is a realm of diverse labeling needs. With expansive rolls, large barcode labels maximize efficiency for inventory control. But for those small warning messages, fanfold labels are the winning ticket. Your vehicles deserve the best in every label.